Do It Yourself encanamento torneira Dicas de reparo, DIY encanamento torneira reparação Dicas sobre BALL-Tipo de torneira, CART-Tipo de torneira, DISC-Tipo de torneira, STEM-Tipo de torneira.

China Sanliv fornece vários Taps, Torneiras, Misturadores, Acessórios, válvula angular, ball bibcock, ball faucet, válvula de esfera, acessório quarto de banho, acessórios de banheiro, banheiro, bidê, bloco, escova, ferro fundido, válvula de retenção, coluna, massagem computadorizada, pólo de extensão, apropriado, fixação, válvula flutuante, chão, foot tub, foot valve, garden steel furniture, gate valve, glass basin set, glass basin, glass wash basin, home improvement, Jacuzzi, Kitchenn, lithopone, malleable pipe’s fitting, malleable, manhole cover, marble, massage shower, mirror, batedeira, mosaic, nail, nut, plumber, plumbing, pole, ferrugem, sanitary fixture, sanitary ware, sanitary, parafuso, shower box, shower tray, single faucet, single mixer, sink, slab, steam bathroom, toque, tile, two handle faucet, two handle mixer, válvula, wash basin, torneira, water heater, water mixer, water, wooden floor.

BALL-TYPE FAUCET | CART-Tipo de torneira | DISC-Tipo de torneira | STEM-Tipo de torneira

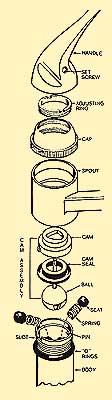

- Shut off water supply valves then drain lines by turning faucet on.

- Use an allen wrench to loosen the set screw holding the handle in place and remove handle.

- Loosen and remove the adjusting ring by using the special wrench provided in the repair kit.

- To remove cap, use pliers and turn counterclockwise. Protect cap finish with cloth.

- Remove spout assembly.

- Remove cam assembly by pulling up on ball shaft. You may need to use pliers.

- Removing seats and springs is best done by inserting a pencil or sharp tool into the seat assembly and gently lifting it out. Check and clean inlet ports before replacing seats and springs.

- To replace “O” rings on body, use a sharp tool to pry away from body. Roll new correct size “O” ring into place.

- When reassembling, be sure to align slot in ball with pin in body and key on cam with slot in body.

- Hand-tighten the cap, then screw adjusting ring into place with special wrench and replace handle. Turn on water and check for leaks. Se necessário, further tighten adjusting ring.

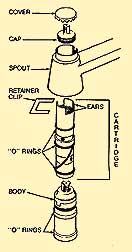

- Shut off water supply valves then drain lines by turning faucet on.

- Pry off decorative cover and remove screw cap.

- Pull spout assembly off.

- Pull retainer clip from its slot.

- Using pliers, lift cartridge out of body. Note position of cartridge ears so that when replacing, they are in identical position.

- Remove “O” rings by prying away from body and rolling new ones into place, or replace entire cartridge.

- Reverse procedure for reassembly.

- Shut off water supply valves and drain lines by turning faucet on.

- Lift handle up as far as possible and loosen set screw.

- Lift handle off and unscrew cap.

- Loosen screws holding ceramic disc cartridge in body and lift cartridge out.

- On underside of cartridge are the set of seals that should be replaced. Check and clean inlet ports.

- Reassemble by reversing above procedure, being sure cartridge holes align with inlet ports.

- Shut off water supply valves then drain lines by turning both faucet handles on.

- Pry off decorative cap on handle and remove screw holding handle.

- Force suavemente fora pega com uma chave de fenda ou usar um identificador de extrator torneira.

- Use pliers or wrench to remove stem locknut/bonnet.

- Depending on style of faucet, either unscrew stem or lift up to remove stem cartridge from faucet body.

- To replace stem washer, remove brass screw (fig.3) and replace washer.

- To resurface a worn or pitted faucet seat, insert faucet reseating tool as shown in Fig.4. Press lightly and turn handle clockwise several times. Check for smoothness and be sure to remove filings with a damp cloth.

- To remove an old seat, use faucet wrench (fig.5) and turn counter- clockwise, then lift out. when installing a new seat, use pipe joint compound on outside threads of the seat to ensure a good seal.

- Leaks at the faucet handle can usually be stopped by replacing the packing washer (fig.6). If you do not have or cannot get the correct washer, string packing (fig.7) can be wound around the stem clockwise, using 1-1/2 times as much thickness as would be required to fill the packing nut. When the nut is tightened, the packing compresses into solid form and acts as a seal.

- Newer cartridge stems simply require the replacement of “O” rings to eliminate leaks.