Beer faucet lock keeps the kids and neighbors from stealing your beer! A draft beer system can be divided into three equipment categories: Cooling (Refrigeration), Beer Faucet Lock and Beer Flow, Gas Pressure. Let us go details as below:

Cooling (Refrigeration)

There are many configurations for cooling and storing keg beer. These include refrigerators which also known as Kegerators, Mobile Bar units and walk-in room coolers. A less expensive method of storing beer is to convert a food refrigerator or freezer into a kegerator (see Keg Conversion Kit and our How-to Workshop). All provide the same function by storing the keg under refrigeration at a constant 38ºF temperature.

Beer Flow Components

The components of a draft beer system include all the equipment from the keg to the faucet. These components include the Keg, the Keg Coupler (Keg Tap), brewery approved Beer and Gas Line tubing and associated Fittings, Beer Shank assembly and the Beer Faucet. In a counter top dispensing application, a Beer Tower is used. The Beer Tower assembly commonly includes a Beer Line & Fitting, Beer Shank assembly and a Faucet.

The first component is the Keg which contains a valve with a stainless beer flow tube. Most North American Brewers use a ½ barrel also known as a full size keg (15.5 gallons) as the standard keg or a ¼ barrel (7.5 gallons).

The beer in the keg contains CO2 which is naturally produced during the fermentation process. The level of CO2 in the beer is determined by the brewer and type of beer in the keg (lager, ales, stouts, etc.) The level of CO2 varies by type of beer and because of these differences the amount of Gas Pressure applied to the keg will also vary to maintain the proper level of CO2 in the beer during the dispensing process.

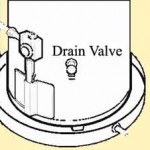

The Keg Coupler, a.k.a. Keg Tap, is the Beer Flow component that opens the valve in the keg and allows gas pressure to enter the keg and for beer to flow out. Not all breweries use the same type of keg valve and beer coupler (keg tap). See our Beer Brand Coupler Reference List. From the Keg Coupler, beer will flow through hose nipples and brewery approved Beer Line (flexible tubing) to the Beer Shank assembly and out the Beer Faucet.

The diameter and length of the beer line plays a major role in controlling the speed of the beer flow at the Beer Faucet. In most Direct Draw refrigerator draft beer systems (Kegerators) 3/16″ (inside diameter) beer line is used, in Glycol Cooled draft beer systems where the beers lines can run up to 500 feet (a.k.a. long draw systems) the Beer Line diameter and material specification will vary according to the system requirements.

In Air-Cooled systems (maximum run length 30 feet) the Beer Line diameter and material specification will vary according to the system requirements, and in Wall Mount direct draw draft beer system the shank assembly connects to a wall mount drain tray assembly and in most cases 3/16″ (inside diameter) beer line is used.

The Beer Faucet is the most visible beer flow component of the draft Beer System. The Beer Faucet is used to open the system (pour the beer) and close the system (stop pouring the beer). Beer faucets are also known as Taps or Spigots. The Beer Faucet connects to the Beer Shank assembly by interlocking teeth between the back end of the beer faucet (female connection) and the Beer Shank (male connection) and is tightened with a special Faucet Wrench that connects to the Beer Shank coupling nut through a series of holes located on the coupling nut.

Gas Pressure Components

These components supplying pressure to the beer keg from the gas source. Starting with the Gas Cylinder (a.k.a. Air Tank). Gas Cylinders include a shut off valve to open and close the gas supply and are manufactured in either aluminum or steel and hold CO2 or CO2 / Nitrogen blend (a.k.a. mixed gas) for systems and products that require a mixed gas pressure source (stouts, etc).

A CO2 Regulator regulates the pressure from the Gas Cylinder (high pressure source) to the keg coupler (keg tap) connected to the keg valve in the keg (low pressure) where a brewery recommended pressure is prescribed (generally 12-14 lbs in Kegerators). A Gas Regulator contains a manual adjusting screw or knob to regulate the amount of pressure supplied to the keg. A properly adjusted and functioning Gas Regulator is critically important to maintaining the proper level of CO2 in the beer, too much CO2 Gas Pressure may add CO2 to the beer and cause foaming problems and too little CO2 Gas Pressure may cause CO2 to release from the beer causing a flat beer.